Shenzhen Youseetech co., Limited

China Manufactory and Office: Heping Village, Fuyong Street, Bao'an District, Shenzhen City, Guangdong Province, China

+8613924609515

Whatsapp/Wechat/Linkedin +8613924609515

youseetech@youseetech.com

Colombia Office: Calle 48 # 53 - 53, Medellín, Antioquia, Colombia

+57 301 3164298

Whatsapp +57 301 3164298

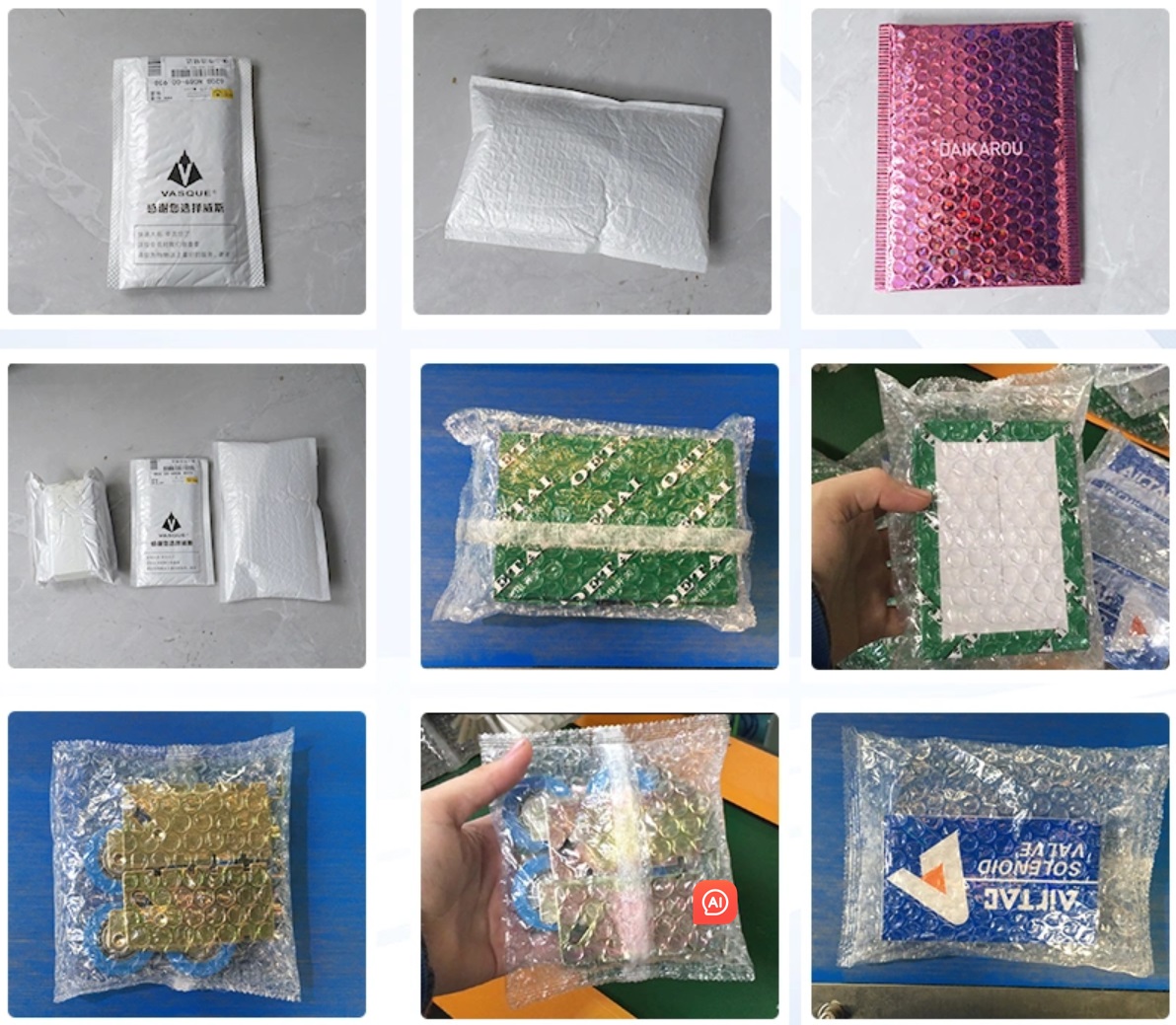

Suitable for food boxes, daily necessities, hardware accessories, express delivery, stationery, electronic products, etc.

1. Scope of application

It is suitable for packaging of various types of clothing, footwear, skin care products, daily necessities,

toys, books and other department store products. It can be directly used in the assembly line to quickly

package bubble film, print e-commerce express delivery orders, label and inkjet code, etc.

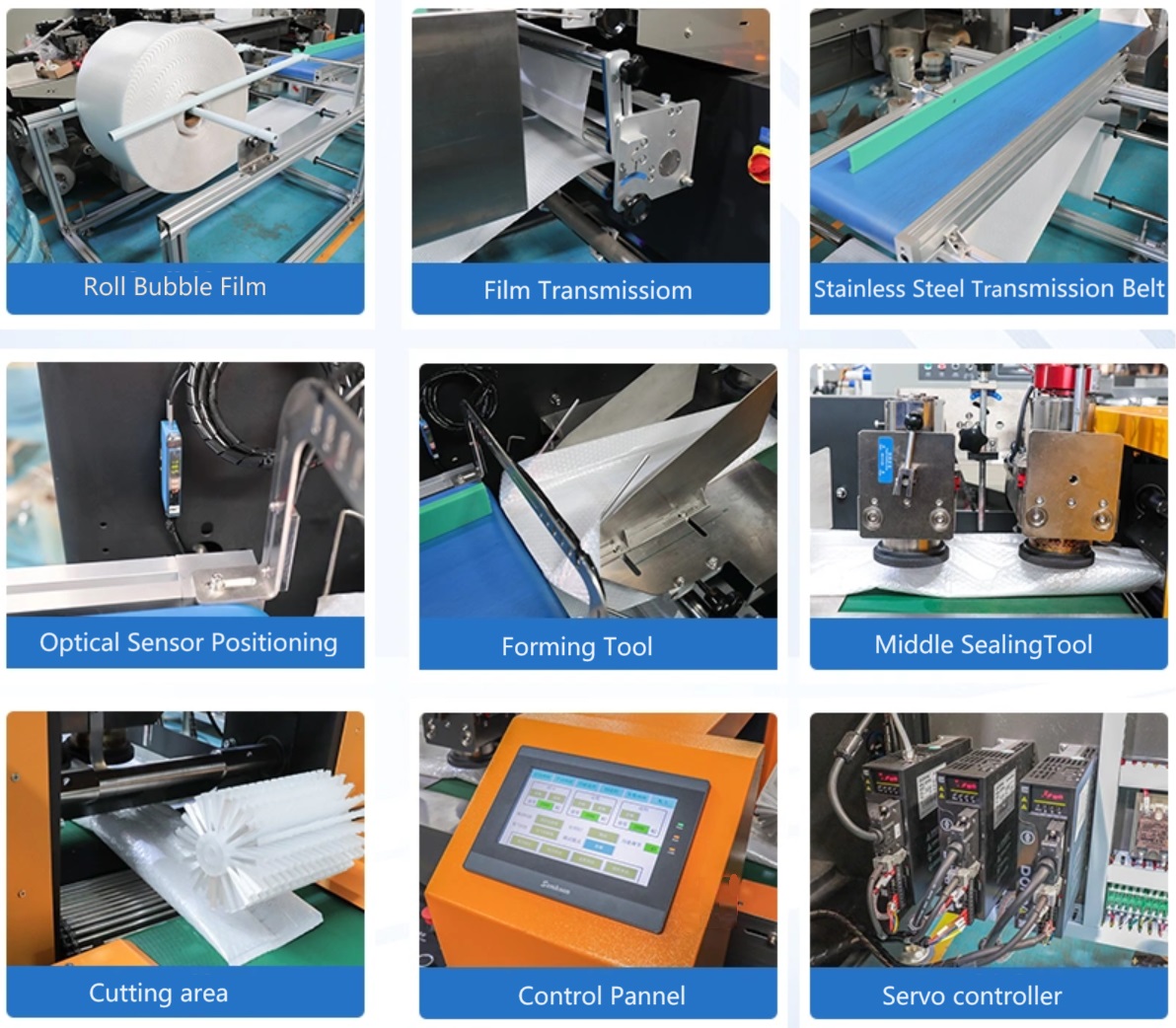

2. Functional features

1. There is no limit on packaging length, using advanced optical fiber sensors to automatically identify

product length and automatically seal and cut packaging bags.

2. There is no need to fix the product placement position, and the packaging spacing can be automatically

identified through sensors.

3. Through servo control of the feeding and paper feeding structure, the infinite speed change function

is realized and the operation is simpler.

4. The control adopts adjustment procedures and can be upgraded and added to the system control

points according to user needs.

1. Scope of application

It is suitable for packaging of various types of clothing, footwear, skin care products, daily necessities,

toys, books and other department store products. It can be directly used in the assembly line to quickly

package bubble film, print e-commerce express delivery orders, label and inkjet code, etc.

2. Functional features

1. There is no limit on packaging length, using advanced optical fiber sensors to automatically identify

product length and automatically seal and cut packaging bags.

2. There is no need to fix the product placement position, and the packaging spacing can be automatically

identified through sensors.

3. Through servo control of the feeding and paper feeding structure, the infinite speed change function

is realized and the operation is simpler.

4. The control adopts adjustment procedures and can be upgraded and added to the system control

points according to user needs.

https://wa.me/message/UZARC7WYGMLKH1

https://wa.me/message/W6ZZG6HB3X7FO1