Shenzhen Youseetech co., Limited

China Manufactory and Office: Heping Village, Fuyong Street, Bao'an District, Shenzhen City, Guangdong Province, China

+8613924609515

Whatsapp/Wechat/Linkedin +8613924609515

youseetech@youseetech.com

Colombia Office: Calle 48 # 53 - 53, Medellín, Antioquia, Colombia

+57 301 3164298

Whatsapp +57 301 3164298

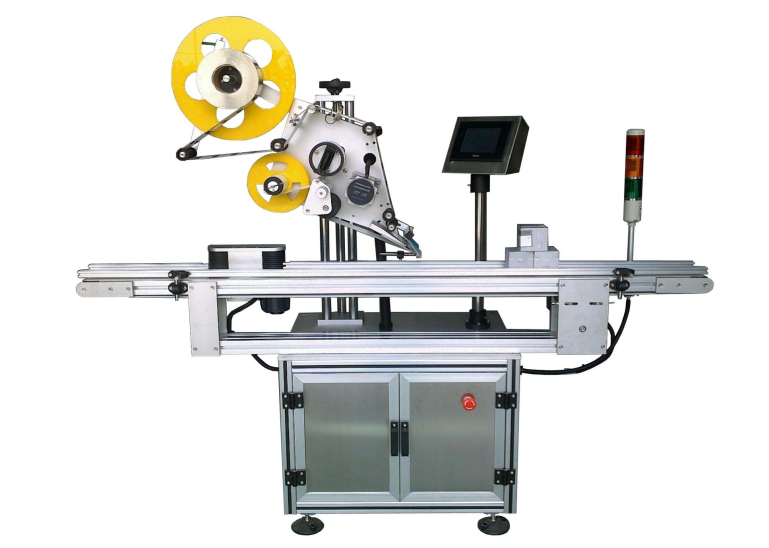

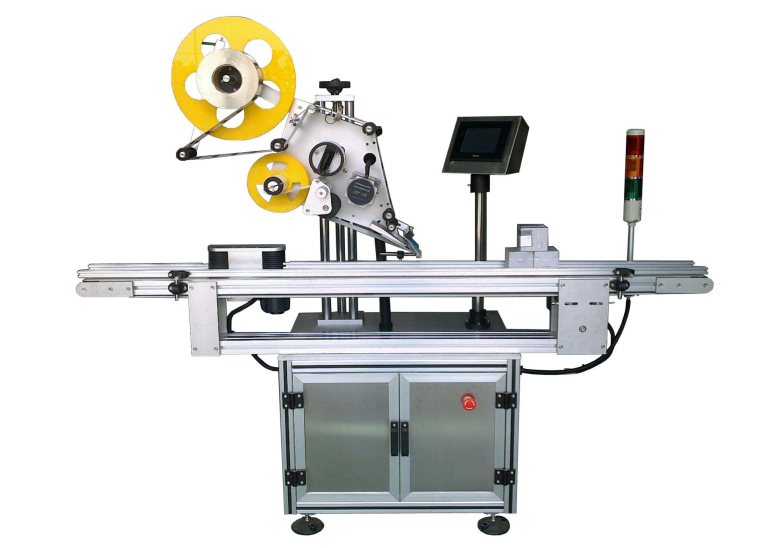

Fully automatic upper and lower flat labeling machine for mobile phone protective films, widely used in mobile phone, IT, electronics, hardware and other industries.

Fully automatic upper and lower flat labeling machine for mobile phone protective films, widely used

in mobile phone, IT, electronics, hardware and other industries. It is specially used for various types of

mobile phone protective films, laptop protective films, etc. It can paste an easy-pull label on the upper

and lower sides at the same time. It has automatic separation Film, automatic conveying, automatic

labeling functions, high labeling accuracy and fast speed. A suction-type card sorting mechanism can

be used to ensure that the protective film is not scratched.

1. Basic use

Specially used for various types of mobile phone protective films, laptop protective films, etc., affixing an

easy-pull label to the top and bottom at the same time. It has the functions of automatic film separation,

automatic transportation, and automatic labeling. The labeling accuracy is high and the speed is fast.

A suction-type card sorting mechanism can be used to ensure that the protective film is not scratched.

2. Scope of application

Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

Applicable products: Products that require labels or films to be attached to protective films or cards.

Application industries: widely used in mobile phones, IT, electronics, hardware and other industries.

Application examples: cardboard card labeling, mobile phone protective film labeling, tablet protective

film labeling, etc.

3. Working process

*Core working principle: The sensor detects the passing of the product and transmits a signal back to

the labeling control system. At the appropriate position, the control system controls the motor to send

out the label and attach it to the position of the product to be labeled. The attaching action of a label is

completed.

*Operation process: Place the product -> Separate and transport the product (automatically implemented

by the equipment) -> Label (automatically implemented by the equipment) -> Collect the labeled products

(automatically implemented by the equipment) -> Take away the product.

4. Technical parameters: (The following are the technical parameters of standard models, other special

requirements and functions can be customized).

Labeling accuracy:±1mm (excluding label and product's tolerance)

Bidding speed: Servo: Step:19m/min, 25m/min

Labeling speed: Step:40~120pcs/min Servo:60~200pcs/min

Applicable product size: Length:60mm~150mm Width:40mm~150mm

Applicable tags size: Length: 6mm~50mm, Label width (backing paper width/mm): 6mm~70mm

Applicable roll labels size:

Label roll outer diameter (mm) 280mm,Inner diameter of label roll (mm): 75mm

Applicable power supply : 220V/50Hz

Power:

Frequency conversion + traction stepper: 880W, Frequency conversion + traction servo: 1330W

Speed regulation + traction step: 600W, Speed regulation + traction servo: 1150W

Total Weight: About 160kg

Overall size

(length*width*height) 2200mm*950mm*1600mm

5. Functional features

◆ Card sorting is stable, using advanced vacuum suction-sorting-reverse wheel technology to sort cards, and

the sorting rate of cards and protective films is much higher than that of ordinary card sorting mechanisms;

◆ The card labeling speed is high, and the stable speed can reach more than 200 pieces/minute for various

protective films;

◆ It has a wide range of applications and can be used for labeling various protective films and card items;

◆ The labeling accuracy is stable, and the product is conveyed by clamping the product up and down. The

conveying is stable and the labeling accuracy is ensured;

◆ The ingenious design of the structural combination of mechanical adjustment parts and label winding, and

the 6 degrees of freedom fine adjustment of the labeling position are convenient, making the conversion

between different products and label winding simple and time-saving;

◆ Intelligent control, automatic photoelectric tracking, with the functions of labeling nothing, automatic

correction without labels and automatic label detection to prevent missed labeling and label waste;

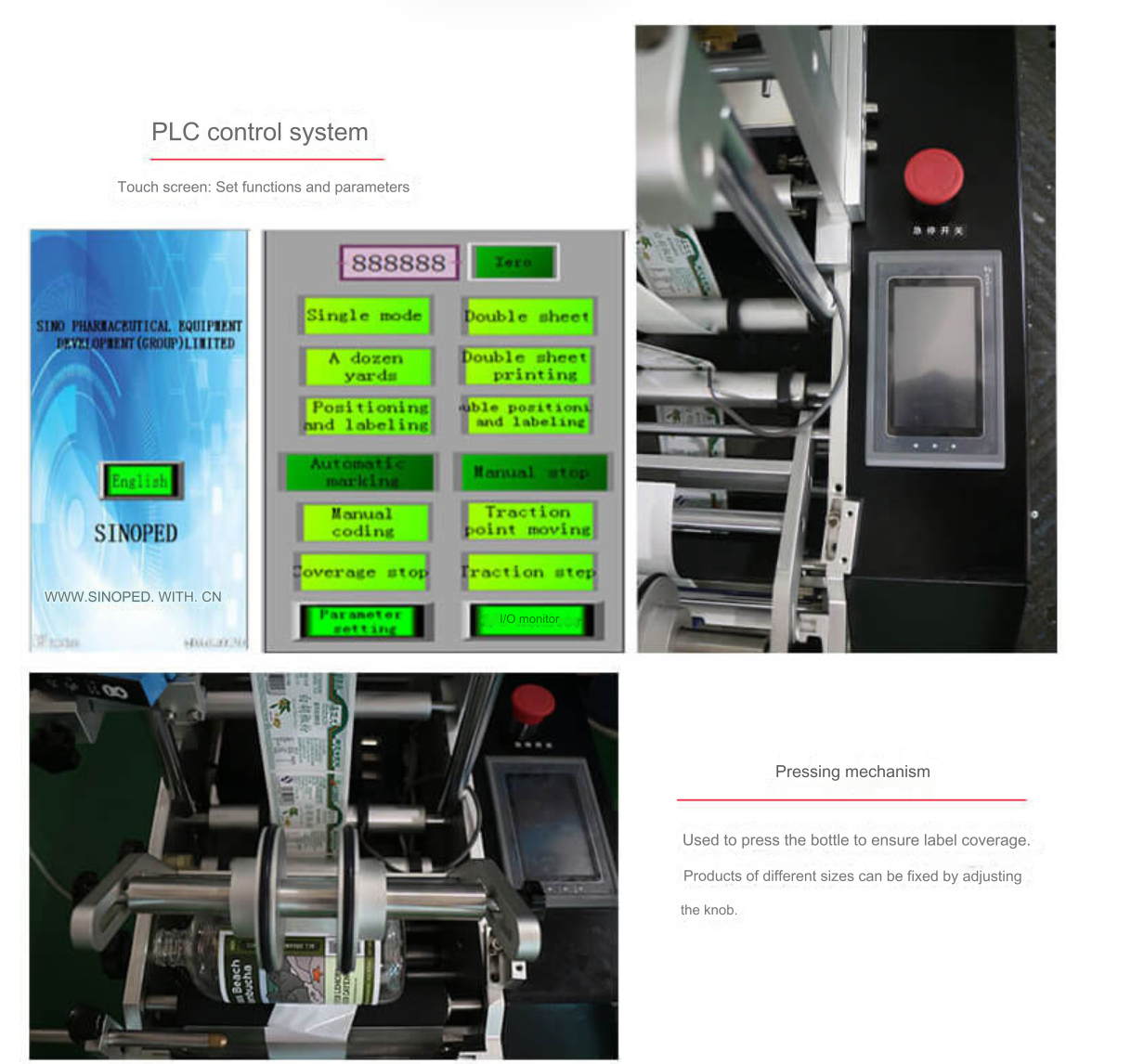

◆ High stability, the wear-resistant electronic control system composed of Panasonic PLC + Weilon touch

screen + Panasonic needle electric eye + German Sik label electric eye supports 7×18 hours of operation of the equipment;

◆ It has fault alarm function, production counting function, power saving function, production number

setting prompt function, and parameter setting protection function.

6. Optional functions and components

①Thermal coding/inkjet coding function;

②Automatic material collection function (considered based on product);

③Add labeling device;

④Other functions (customized according to customer requirements).

https://wa.me/message/UZARC7WYGMLKH1

https://wa.me/message/W6ZZG6HB3X7FO1